Products

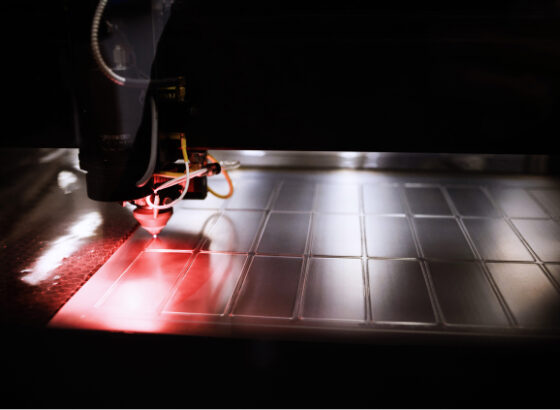

Flexible Dies

Solid Dies

Anvils

Magnetic Cylinders

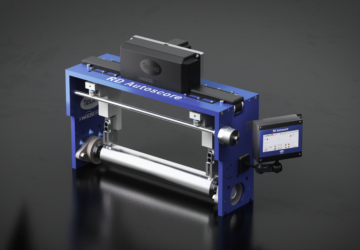

Slitting and Scoring Solutions

Material Movement Solid Dies

Performance Coating Treatments

Print Sleeves and Print Cylinders

AGMA Gears

Additional Supporting Products

RotoMetrics

RotoMetrics is the Maxcess brand of rotary cutting die solutions and services. A team of world-class application advisers, engineers, master technicians, craftsmen and specialists have created industry-leading solutions for more than 60 years.

Learn more about RotoMetricsRotary Cutting Die Resources

Find helpful guides, documentation, product sheets and more for all of our rotary cutting die products.