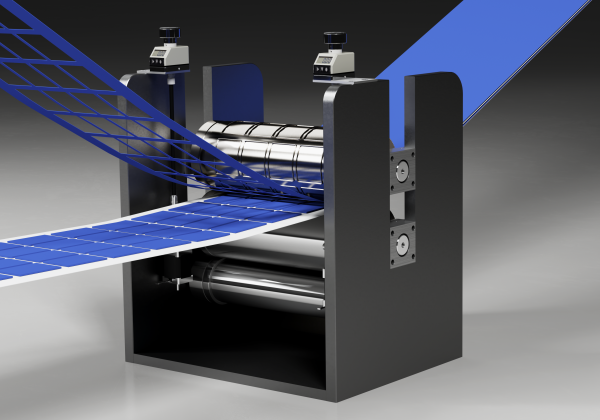

Anvils

The perfect match for a precise cut

Your converting process has multiple moving parts, and your success relies on every single one of them working together

RotoMetrics unlocks the Power of Precision even with our range of anvil solutions

Our world-class customer service representatives and engineers will work with you to hone the versatility of our anvil solutions to be exactly what you need in order to achieve more consistent and precise die cutting. We offer a range of anvil solutions from simple, effective solutions to our upcoming automated anvils:

- Base Anvils

- Adjustable Clearance Anvils

- RotoAdjust Intelligent Die Station Solution

- AccuAdjust Dual Adjustable Anvils

Anvils Overview

Base Anvils - Perfect match for most precise cut

Product Features

- Fully hardened and ground to a near-mirror finish

- Available either smooth or stepped

- Used for a full range of converting methods

- Available in a variety of custom steel grades

Adjustable Clearance Anvils - infinite and unrestricted adjustability on cut depth

Product Features

- Unrestricted adjustment to the depth of your cut at any range

- Simple external dial control while press is running or stopped

- Fully hardened steel and bearers

- Works great on non Tag & Label applications

- Easily changes with standard press anvils

- Requires no modification of existing die inventories

- No maintenance or calibration required

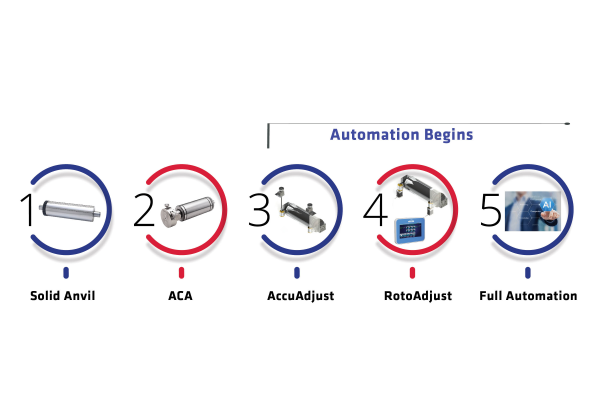

AccuAdjust Dual Adjustable Anvil - a step up to automation

Product Features

- Maintains legacy anvil design for increased durability and uptim

- Cut perfect labels, no matter the liner material

- Independent or simultaneous bearer adjustment for flexibility in die cutting

- Intuitive, digital controller for ease of use

- Adjust on both sides, at standstill or when machine is running for continued uptime

- Easy upgrade path to fully-automated solutions

Our Versa-Cut Anvil has been discontinued and replaced with the new AccuAdjust.

- Tag and Label

- Packaging

- Food and Beverage

- Flexible Packaging

- Corrugated

- Pharmaceutical

- Nonwovens

- Specialty Converting

Related Products

AccuAdjust Dual Adjustable Anvil

AccuAdjust solves liner variability issues and allows easy cutting of PET, Glassine, Kraft and more with a simple turn of a precision digital dial. Cut perfect labels and minimize material consumption no matter the liner material.

RD300 Solid Die

Cut precision parts, thick substrates and thin films or synthetic constructions with ease. The RD300 solid die provides a totally precise performance whether in complex long run to-liner, challenging zero clearance, or complicated metal-to-metal converting projects.

FIFE-500 Web Guiding System

Leverage the latest in web guiding technology and improve efficiency with the cost-effective FIFE-500, ideal for narrow web and nonwoven applications.

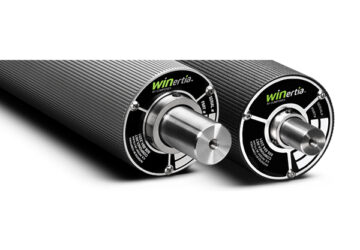

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

Featuring a special air vent design for consistent, reliable performance in demanding environments.