Material Movement Solutions

Optimize uptime through state-of-the-art waste/slug/byproduct removal systems

Customized air, pin and vacuum solutions are specifically engineered for your unique application

EZ Clean solutions to minimize downtime and increase speeds

Material Movement Overview

A comprehensive suite of products engineered to minimize equipment damage and increase your efficiency.

Typically, for Metal to Metal applications, a finished die cut product moves with the liner. Without a material movement solution, the waste moves up the matrix and can potentially cause buildup and, ultimately, equipment damage. RotoMetrics innovated custom die solutions that remove cut-outs from the substrate or carrier based on your unique specifications.

We offer three types of material movement solutions that each provide unique benefits to your die cutting process:

- Air: Compressed air blows away waste or die cut parts from your die

- Vacuum: Picks up waste from the web and pulls it through your die journal

- Pin: Pin Eject pushes pieces away from the die

RD Vacuum Boxes Specs – More efficient converting and prevents waste particle buildup

- Captures pieces of waste blown out of your web

- Easily attaches to your press

- Prevents waste particles from collecting on anvil roll or in gears, thus minimizing your downtime

MultiPort Air Eject Specs – Targeted air blast for a precise and controlled solution

- Uses compressed air and/or vacuum to optimize the removal of material

- Can concentrate air/vacuum at a specific row of cavities cutting

- Can angle target blast of air/vacuum for most precise directional blast

- Can be used with a combination of compressed air and vacuum to select a die cut from the cavity and release it later in the die’s rotation

Focused Air and Air Eject Specs – The power of compressed air prevents equipment damage

- Prevents damage or buildup in a variety of Metal to Metal cutting applications

- Custom calibrated to ensure optimum airflow

- Proprietary air probe aims airflow at a specific row of cavities

Vacuum Dies – The cleanest way to remove waste from the web

- Specifically designed to vacuum small pieces from the web

- Interchangeable punch, lock tight and engraved options

- Minimizes downtime

Pin Eject Dies – Proven and highly efficient way to eject parts, slugs, byproducts or waste

- Assists in removal of materials from the web using built-in compression system

- Ideal in high speed, high volume converting applications

- Prevents buildup of small die cut slugs

- Pin Switch Eject Dies can replace pins on site

EZ Clean Stripping Roll – faster presses with easy cleaning

- Waste matrix more easily separated from web

- Adjustable for any label layout

- Run up to 50% faster

EZ Clean Idler / Pathing Roll – faster presses with easy cleaning

- Improved web tracking

- No need to stop press for partial waste matrix

- Easy roll cleaning

- Tag and Label

- Packaging

- Food and Beverage

- Flexible Packaging

- Corrugated

- Pharmaceutical

- Nonwovens

- Specialty Converting

Related Products

RD100 Solid Die

The RD100 solid die is crafted with superior steel and heat treatment for durability and longevity. As a value-oriented, metal-to-metal converting solid die, the RD100 is capable of cutting most substrates.

RD250 Solid Die

As a superior solid die, the RD250 is ideal for to-liner and metal-to-metal applications. Enhanced with dedicated steel and machine finishing for precise blade profiles and tighter tolerances ensure it will produce cost-effective results and resolve converting challenges.

RotoRepel™ Adhesive Control Treatment

RotoRepel™ offers comprehensive adhesive control benefits far beyond nonstick properties, improving overall die and press performance in several ways for more longevity and better efficiency.

FIFE-500 Web Guiding System

Leverage the latest in web guiding technology and improve efficiency with the cost-effective FIFE-500, ideal for narrow web and nonwoven applications.

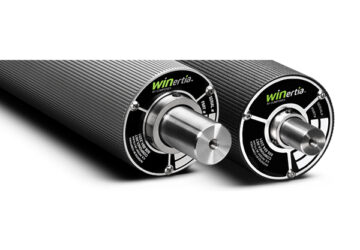

WINertia™ AV-Air Vent Aluminum Dead Shaft Idler

Featuring a special air vent design for consistent, reliable performance in demanding environments.